![]()

Retroflex.com

U.S. | Retroflex, Incorporated | 1205 Broadway Street, Wrightstown, WI 54180 | Toll Free 877.532.5600 | Phone 920.532.4850

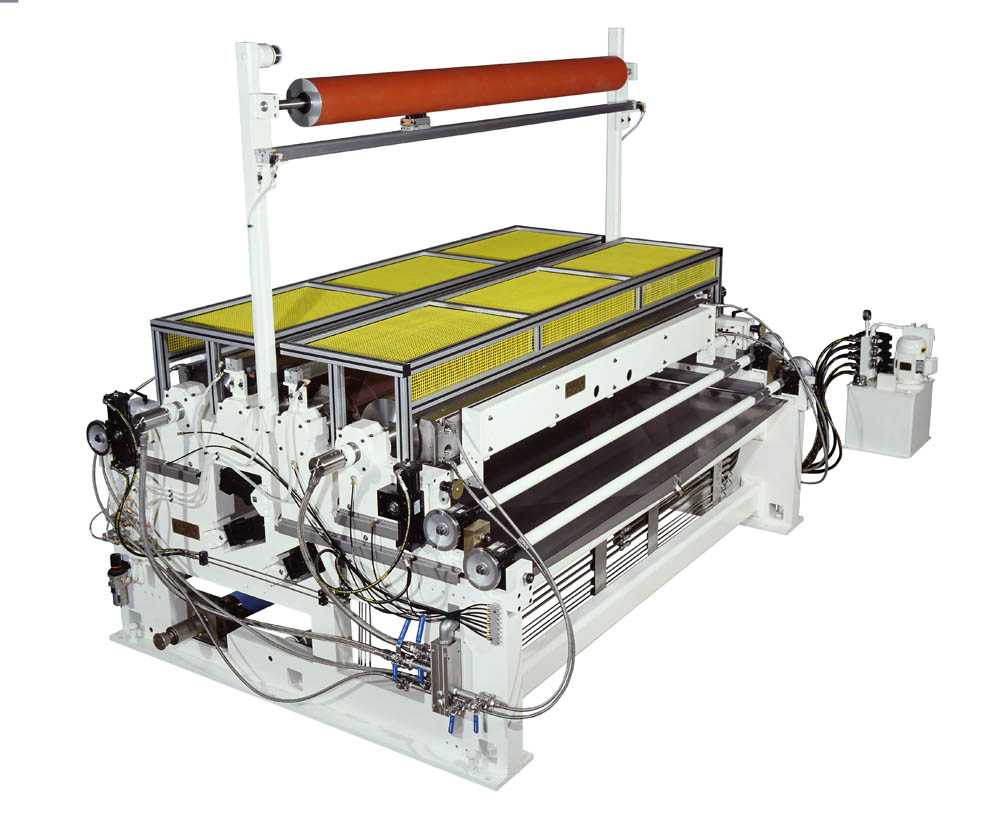

Flexo and Gravure Coaters

Flexo and Gravure Coaters

Retroflex builds both custom and standard coaters for operating speeds up to 3,750 fpm and web widths of 10 to 150

inches.

Retroflex single- and two-side coaters are available in direct gravure, offset gravure, kiss coating and flexographic

designs.

Reverse angle and trailing doctor blade systems, as well as fountain-type fluid metering systems, are available for

applying nearly any fluid. Temperature controlled rolls and doctor blade systems are available for specialty fluids such

as dry or wet wax, lotions, or anti-bacterial solutions.

| Standard Features (most models) |

|---|

| Ceramic Laser Engraved Rolls |

| Chambered Doctoring Systems |

| Pneumatic Deck Lock-Up |

| Linear Bearings for Roll Frames |

| Optional Features (most models) |

|---|

| Sleeved Transfer Rolls |

| Temperature Controlled Rolls/Chambers |

| Servo Controlled Roll Positioning |

| A.C. or Gearless Servo Drive Systems |

| Pre or Post Chill Roll Sections |

| Pre or Post Heat Roll Sections |

| Tension Isolation Nip Roll System |

| Unwinds and Rewinds (single or turret) |

| Drying/Curing Systems (hot air, IR, UV, EB or compressed air) |

| Common Applications |

|---|

| Primer Coating/Printing inline with Digital Printers |

| Lotion Coating |

| Antibacterial Coat |

| Wet Wax and/or Dry Wax Coating |

| Varnish |

| Tinting/Printing (offline or in line with a corrugator) |

All Retroflex machinery comes with component assembly drawings and operating manuals.