![]()

Retroflex.com

U.S. | Retroflex, Incorporated | 1205 Broadway Street, Wrightstown, WI 54180 | Toll Free 877.532.5600 | Phone 920.532.4850

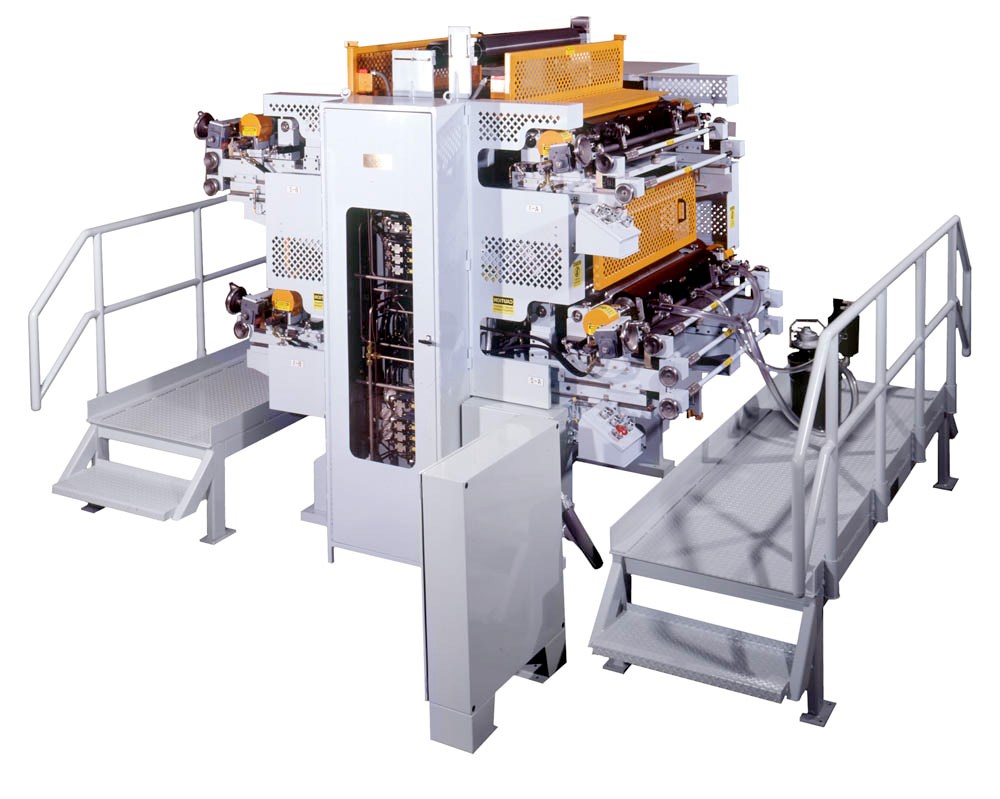

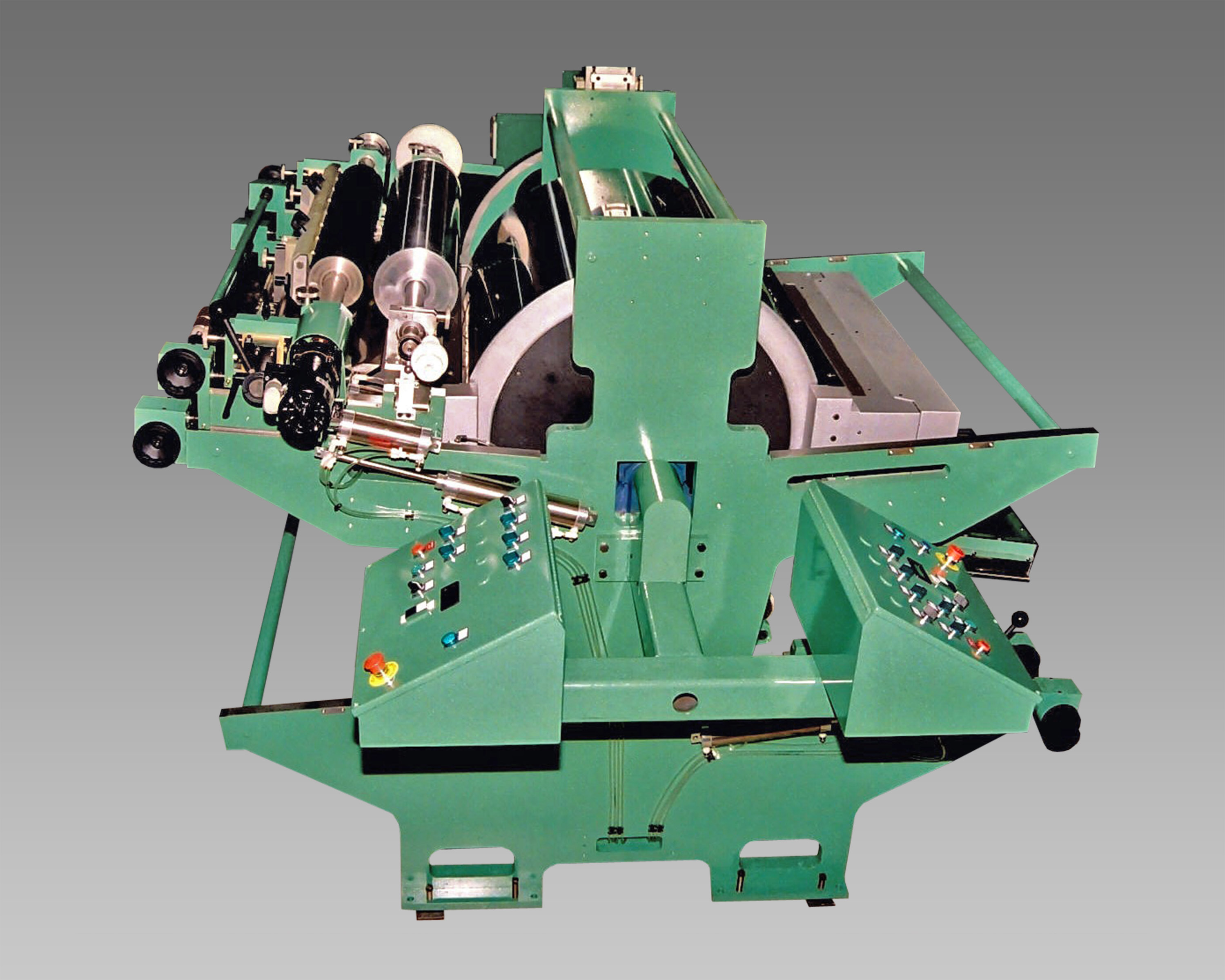

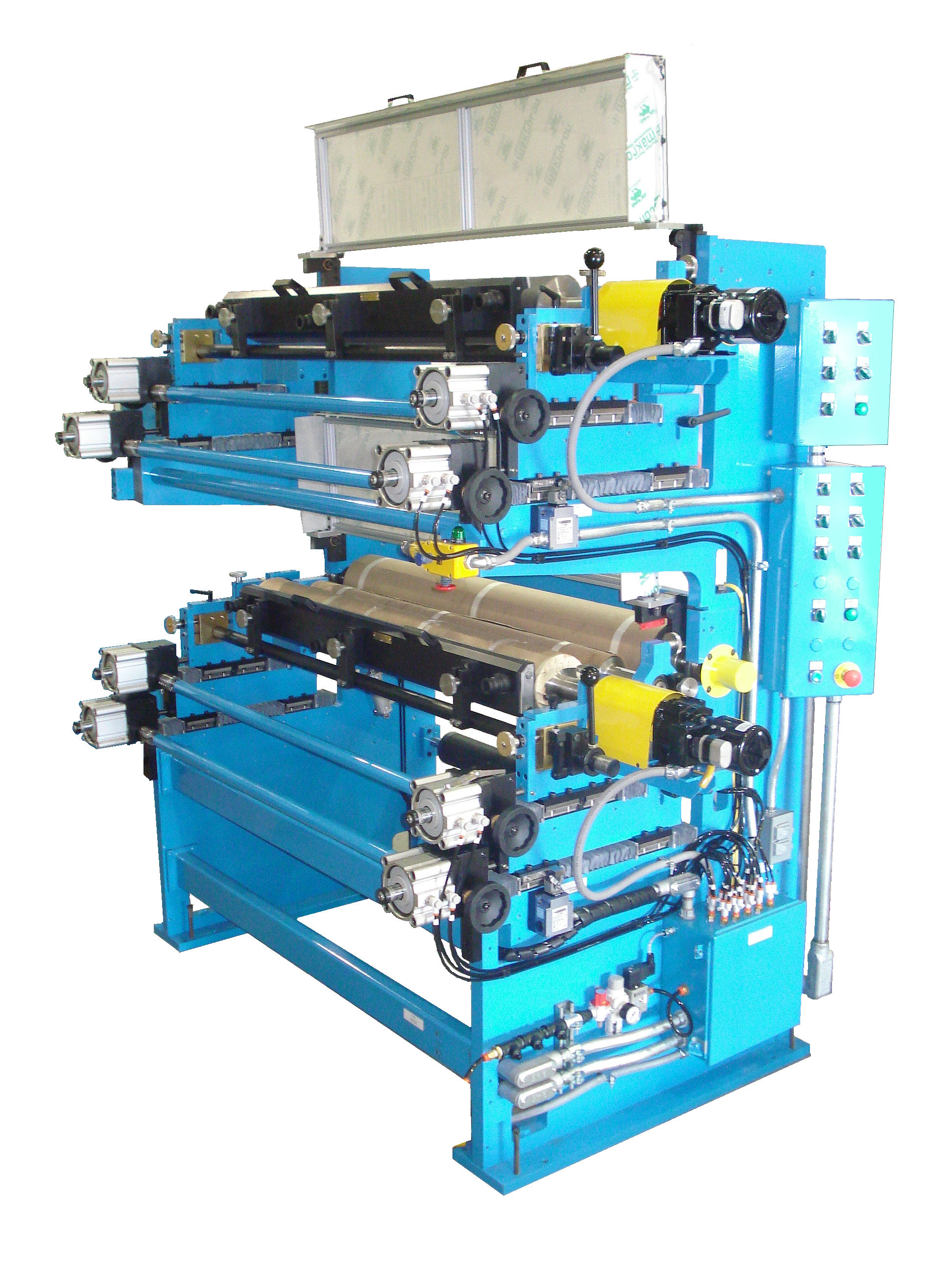

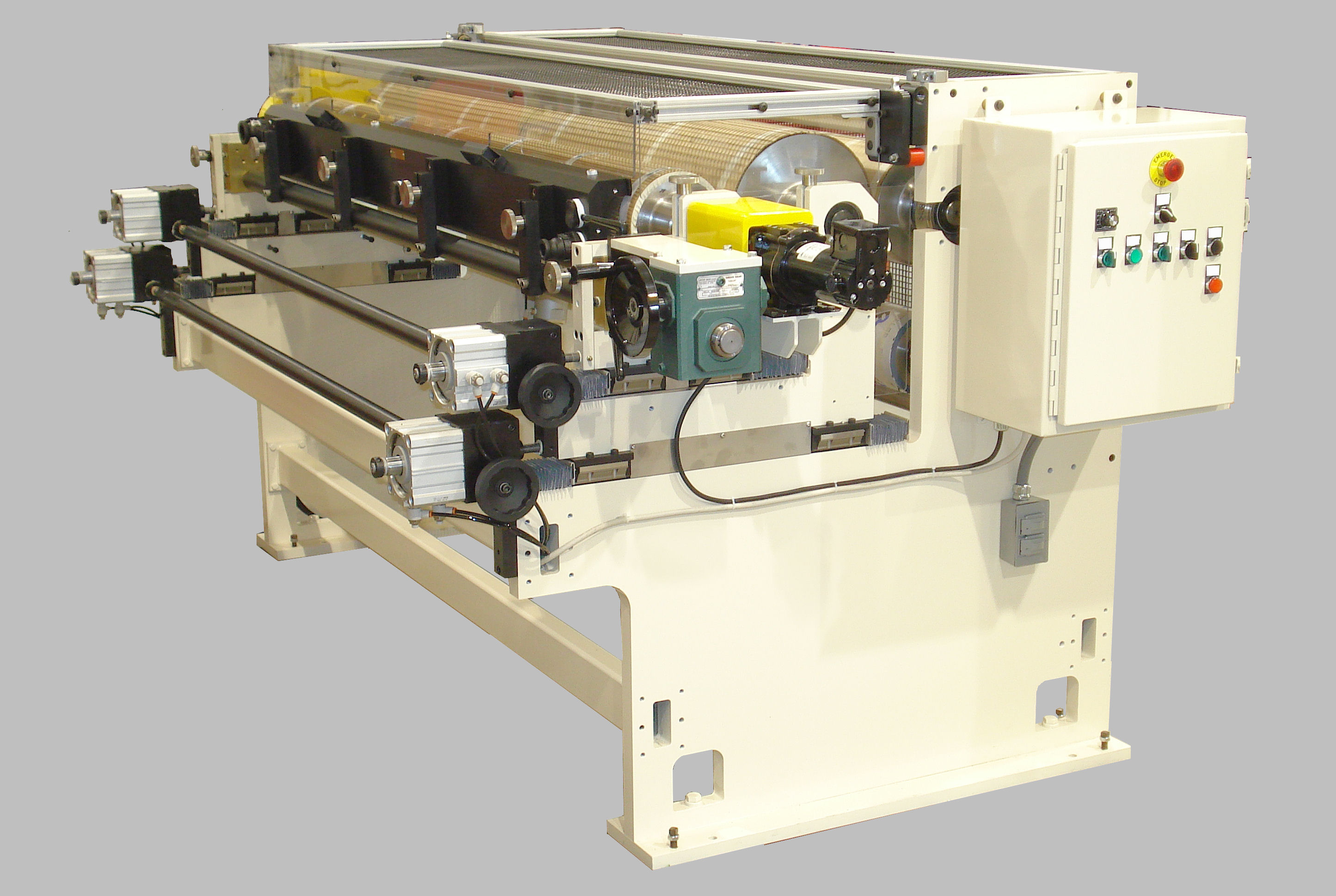

K-Series Flexo Presses — Narrow to Mid-Width

Designed To Meet More Demanding Applications For Narrow To Mid-Width Flexo Webs

These flexo presses can be built for both narrow to medium web widths and are equipped with the Retroflex chambered doctor blade system, ceramic anilox roll, and pneumatic throw-off. Most K-Series flexo presses are designed to run up to 1,000 fpm, and sometimes higher under certain conditions.

| Standard Features On Most K-Series Flexo Presses | |

|---|---|

| Web Widths: | 20 to 70 Inches |

| Web Speeds: | Up to 1,000 FPM |

| Configuration: | Inline, Stack or CI |

| Colors: | Up to 10 Colors |

| Doctor Blade System: | Retroflex RADBS Chambered System |

| Ceramic Anilox Roll | |

| Pneumatic Throw-Off | |

| Optional Features on most K-Series Flexo Presses | |

|---|---|

| Precision-Ground CI Drum | |

| Circumferential Registration (manual) | |

| Tension Isolation Nip Roll System | |

| Sleeved Anilox/Plate Rolls | |

| Bridge System For Sleeves | |

| Auto-Flush Systems For Ink Chambers | |

| Gearless Servo Drive System | |

| Sleeve Carts And Lifts | |

| Web Inspection Camera | |

| Unwind (single or turret) | |

| Dryer System (hot air, IR, UV, EB or compressed air) | |

| Chill Section |

HD Option

Overall, this is a more robust design with thicker frames and larger roll diameters. The HD Option is typically ordered when larger print repeats and higher speeds are requested.

Ultra Option

The Ultra model features the HD design plus full servo roll positioning, gearless servo drives to the anilox, plate and impression rolls, as well as on-press anilox and plate sleeve changes.